Innovative anti-avalanche barriers: securing a sustainable future

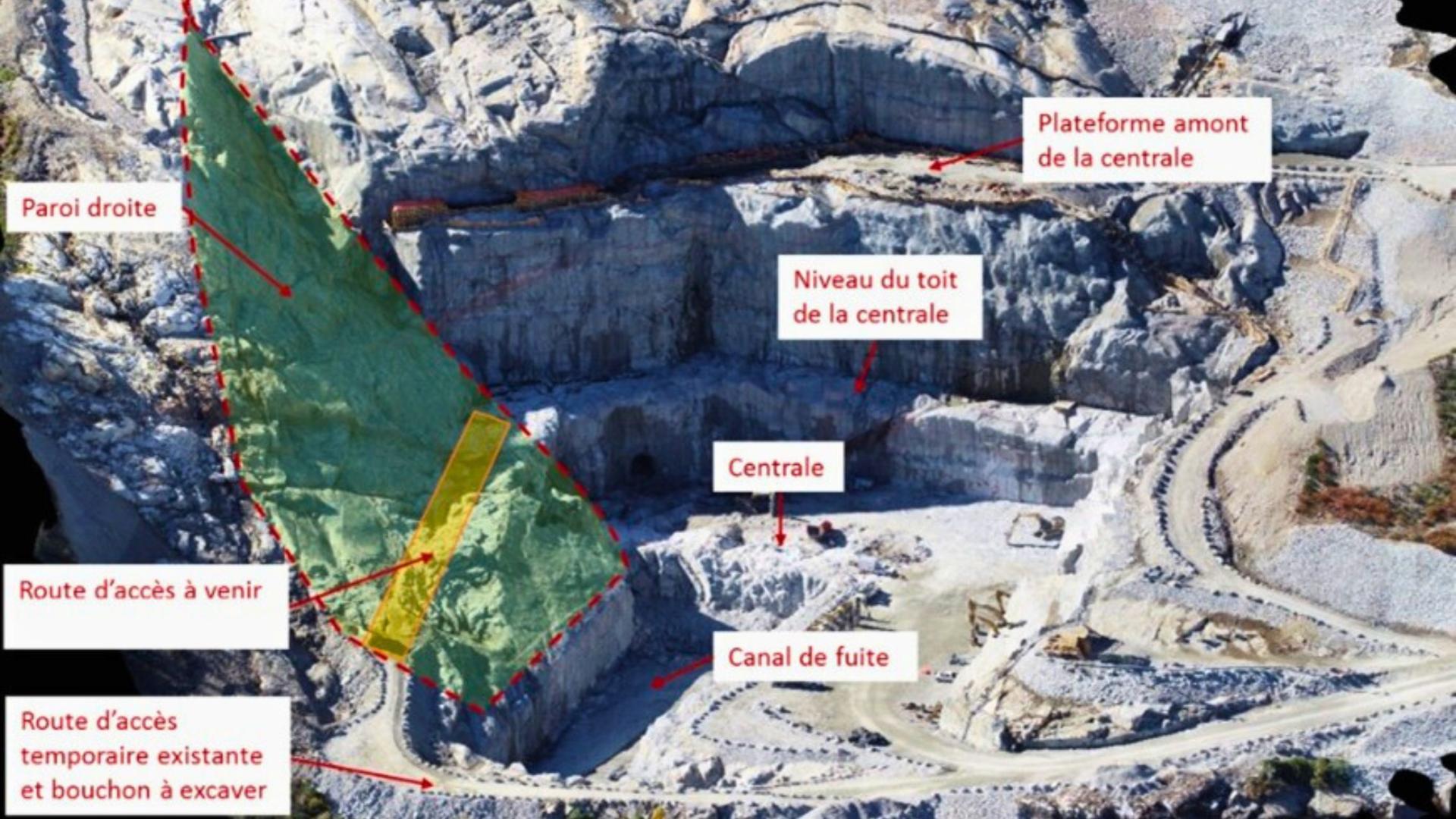

The Romaine 4 hydroelectric complex is an essential and promising project for Quebec. Considering this project’s scale and complexity, many variables had to be considered and extensive civil engineering works had to be undertaken to ensure the project’s success. The construction of the power plant and its tailrace required large-scale excavations in the site’s bedrock. These works created an unusual excavation with a steep 37-degree incline in the right wall adjacent to the power station, caused by the geological and structural rock conditions.

Due to this situation and the strong risk of avalanches it could create, Hydro-Québec initially mandated avalanche specialists to research safe and sustainable solutions in an effort to protect the power plant and its workers.

A collaborative approach anchored in innovation

Following these analyses and resulting recommendations, Englobe proposed the installation of flexible umbrella-type anti-avalanche barriers for technical, economic, aesthetic and safety reasons. It was the first time this type of system was adopted in North America.

Leveraging the long, fruitful collaboration between the two companies, Hydro-Québec mandated the Englobe team to quickly assemble a multidisciplinary national team and to oversee the installation and quality control of every stage of the project. With a short six-month time frame and in collaboration with the specialized Canadian firm Alpine Solution and the client, Englobe executed the onsite data collection for the solution design, and produced both a summary geological map and a 3D topographical survey carried out by drone.

To enhance the process, emphasis was placed on analyzing the snow and its various characteristics, including the identification of snow blades, their arrangement and depth.

With this solid theoretical foundation, the next step was to design the barriers, which proved to be a complex process. Given the barriers’ unique and innovative nature and the site’s geometric characteristics, materials and tools had to be transported to the job site by crane. In addition, workers could only travel to and move around the site by using rope support and rappelling. In total, installed 49 barriers were installed on this site.

With its structured and innovative approach, Englobe mobilized key human and technical resources to devise a feasible, sustainable and safe anti-avalanche barrier system.

Protecting human life sustainably and responsibly

Given the bedrock wall’s steep incline and resulting access limitations, the barriers had to be installed by highly specialized professionals with advanced mountaineering skills in addition to their technical expertise, as they were required to carry out their operations while being supported by ropes. These constraints also meant that materials and tools had to be transported by a crane located on temporary access roads, thus enabling the team to comply with the highest H&S standards for this high-risk project.

Englobe made sure to optimize the long-term maintenance costs while securing the protection of Hydro-Québec operations staff and the power plant’s installations. The solution was designed with sustainable materials with a 30- to 40-year lifespan. The team also developed maintenance manuals, in which meticulous inspections were mandated every five years.

Protecting human life was always a key comonent of this project. This is why the team conducted thorough health and safety risk assessments to optimize its design, production and installation choices. These analyses were forwarded to Hydro-Québec, out of concern for the integrity and proper conduct of their overall operations on this site.

By contributing to Quebec’s energy future, in a context of climate change and resource scarcity, we’ve helped ensure that future generations will be able to benefit from clean, renewable, affordable and safe energy.

Focused on the future

Anchored in a long-term design methodology, the anti-avalanche barriers were conceived not as an ad-hoc fix to a temporary situation, but instead as a solution that takes into account the recurring nature of this type of natural disaster, which has been amplified by climate change. Considering that all types of infrastructure, no matter their scale and complexity, have a limited lifespan, our solution contributes to enhancing the power plant’s longevity and energy output, while mitigating future breakdowns.

Englobe showed great efficiency from both a management and technical perspective. The multidisciplinary team we assembled enabled us to offer a fully integrated, turnkey service, ranging from analysis to design and implementation.

shares, Guillaume Joyal, Operations Director, Geoengineering, at Englobe

As the proposed system was a first in North America, Englobe was able to gather the material, human and technical resources needed to achieve the project’s objectives. This enabled Hydro-Québec to gain a functional, sustainable solution and the autonomy to maintain it over time.

Best Project Award in the Geotechnical and Materials Engineering

Englobe was recognized with the Best Project Award in the Geotechnical and Materials Engineering category. With our key geotechnical expertise, we contributed to the province’s energy transition, ensuring that future generations will be able to benefit from clean, renewable, affordable and safe energy. A win on this level stands as a powerful reminder of the united strength and talent of our team.

One project at a time, we continue to make a lasting impact in our communities by preserving infrastructure and ensuring human safety.

From left to right: Noureddine Ghlamallah, Vice President, Geosciences - Quebec, Englobe, Guillaume Joyal, Director of Operations, Geoengineering, Englobe and Catherine Ouellette, Project Engineer, Major Infrastructure and Power Projects, Hydro-Québec.